Ruta de navegación

Our stories

Connecting experts and enthusiasts, dreamers and doers, innovators and influencers — explore and experience.

Explore our stories

Menú de navegación

Publicador de contenidos

Back to Previous Page Upal - O2 Tech Tips Duplicate 1

- Listing Title

- Oxygen Sensor Tech Tips

- Listing Subtitle

- Products | O2 Sensors

- Listing Image

- Article Title

- Article Subtitle

- Because engine configurations can vary by vehicle, it’s important to correctly identify the specific positions of all your oxygen sensors – so you replace the correct sensor when one of them fails. The post below provides some guidance in understanding which oxygen sensor to change and a few technical tips to assist in a smooth installation process.

- Article Image

- Summary

-

Sensor Locations

Refer to your vehicle service manual to determine your sensor locations. If the manual is not available, here are some guidelines that apply to most vehicles:

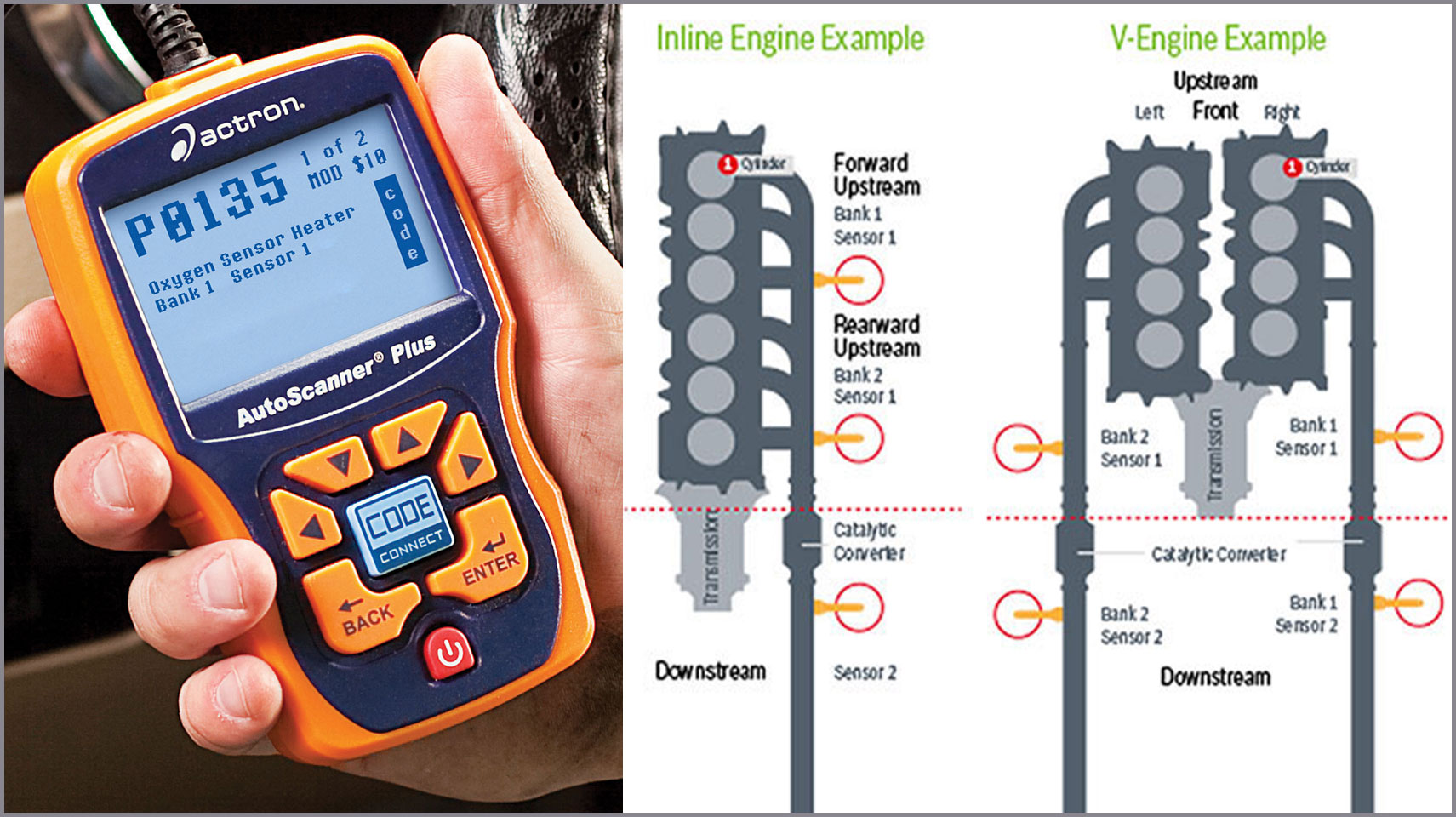

Location by Code

- Car makers generally define Bank 1 as the Bank containing Cylinder 1.

- If you don’t know your Cylinder 1 location, ask your auto parts store associate for a cylinder-number- or firing-order diagram for your vehicle. See example at right.

- Sensor 1 is the upstream sensor and Sensor 2 is generally located after the catalyst (downstream)

- On a 3 sensor per bank system, Sensor 2 is located on the catalyst and Sensor 3 is located after the catalyst.

Catalog Locations

- The front of the engine contains the belt and alternator.

- The transmission is mounted to the rear of the engine.

- Left and right are defined looking from the rear to the front of the engine.

- On rear wheel drive applications, this is the view from the drivers seat.

- Use the bank detail (at left) to determine if you need a forward, rearward, left or right sensor.

- Car makers generally define Bank 1 as the Bank containing Cylinder 1.

- Section 1 Title

- Installation Tip

- Section 1 Image

- Section 1 Body

-

Disconnect the Battery

Many vehicles require a sensor learning trigger from a scan tool after a new sensor is installed. Clearing codes does not initiate this learning process, but often a 5 minute battery disconnect can.

So, not only is having the battery cable disconnected during service recommended for safety, it can also help you avoid unnecessary service.

- Section 2 Title

- Section 2 Image

- Section 2 Body

-

Reference AirBecause Oxygen Sensors require a clean reference air sample to function properly:

- It’s critical that the wiring harness is not damaged during installation.

- The use of dielectric grease, cleaners and other chemicals in the connector or on the sensor can cause permanent damage.

- Section 3 Title

- Section 3 Image

- Section 3 Body

-

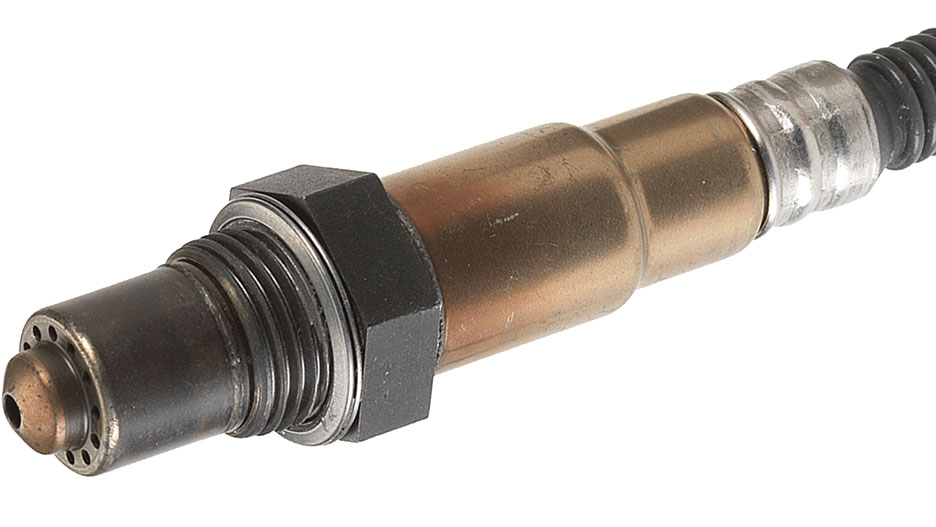

Discolored / Seared Protection Tube Ensures High Quality

- Section 4 Title

- Section 4 Image

- Section 4 Body

-

Some customers have noticed a dark discoloration on Bosch sensors and question if the part is used.

- Rest assured that this discoloration is normal and the result of one of many processes we utilize during manufacturing to ensure quality and performance.

- Section 5 Title

- Section 5 Image

- Section 5 Body

- Section 6 Title

- Section 6 Image

- Section 6 Body